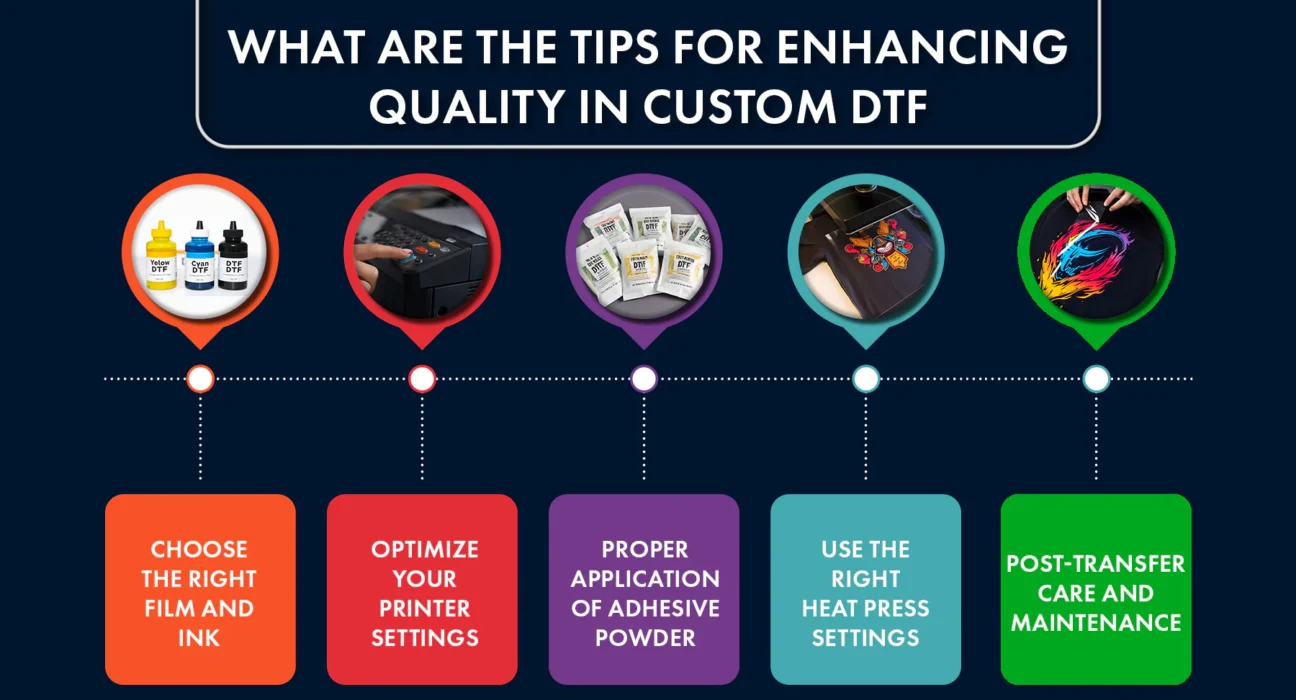

DTF printing has become increasingly popular in the custom printing industry. Whether you’re new to DTF printing or looking to improve your results, selecting the right film and ink is crucial. Let’s explore the key factors to help you make the best choice for your printing needs.

What Makes Quality DTF Film?

The foundation of successful DTF printing starts with selecting the best DTF film. Quality DTF film should have these essential features:

Film Thickness

- Standard thickness ranges from 0.75mm to 1.0mm

- Thicker films (0.95-1.0mm) work better for detailed designs

- Thinner films (0.75-0.85mm) are ideal for simple patterns

- Choose based on your specific application needs

Surface Coating

- PET-based coating ensures proper ink adhesion

- Anti-static treatment prevents dust collection

- Even coating thickness across the entire surface

- Smooth texture for consistent ink transfer

Ink Compatibility

- Must work with both white and color DTF inks

- Should accept standard DTF printing temperatures

- Good ink absorption without bleeding

- Fast drying properties to prevent smudging

Selecting the Right DTF InkInk Quality Indicators

- Color vibrancy and consistency

- White ink opacity level

- Wash resistance (minimum 30 washes)

- Stretch capability without cracking

Essential Ink Properties

- Low viscosity for smooth flow

- Quick-drying formula

- Strong adhesion to powder

- Flexibility after heat curing

Color Management

- Full CMYK color range

- High-quality white ink base

- Consistent color reproduction

- Good mixing capabilities

Technical ConsiderationsPrint Settings

- Temperature: 150-170°C optimal range

- Pressure: Medium to high

- Time: 15-20 seconds for most applications

- Cooling period: 5-10 seconds

Storage Requirements Film Storage:

- Keep in cool, dry place

- Avoid direct sunlight

- Temperature: 20-25°C

- Humidity: 45-55%

Ink Storage:

- Sealed containers

- Room temperature

- Away from heat sources

- Regular stirring before use

Practical Tips for SuccessTesting Process

- Start with small samples

- Test different temperature settings

- Document results

- Adjust based on findings

Quality Control

- Check film coating consistency

- Monitor ink flow and coverage

- Inspect transfer results

- Test wash resistance

Common Issues and Solutions Film Problems:

- Curling: Adjust storage conditions

- Poor adhesion: Check temperature settings

- Bubbling: Reduce heat or pressure

- Incomplete transfer: Increase pressure

Ink Issues:

- Clogging: Regular maintenance required

- Poor coverage: Adjust print settings

- Color inconsistency: Check ink mixing

- Washing problems: Verify curing temperature

Cost ConsiderationsInitial Investment

- Film cost per sheet

- Ink cost per liter

- Powder adhesive expenses

- Equipment requirements

Long-term Value

- Print quality consistency

- Material wastage rate

- Production speed

- Customer satisfaction

For more detailed information about DTF printing supplies and equipment, visit https://www.dtflinko.com/.

Maintenance Tips Daily Care

- Clean print heads

- Check ink levels

- Maintain proper humidity

- Keep work area clean

Weekly Tasks

- Deep clean system

- Check film inventory

- Monitor ink consistency

- Test print quality

Making Your Final ChoiceConsider These Factors:

- Production volume

- Design complexity

- Budget constraints

- Quality requirements

Decision Process:

- Research suppliers

- Request samples

- Test materials

- Compare results

Conclusion

Choosing the right DTF film and ink requires careful consideration of multiple factors. Focus on quality, compatibility, and your specific needs. Start with small quantities for testing, and maintain proper storage and handling procedures. Regular maintenance and quality control will help ensure consistent results. Remember that success in DTF printing comes from finding the right balance between quality materials and proper technique. Take time to test different options and document your results. With the right combination of film and ink, you’ll achieve professional-quality prints that meet your customers’ expectations. Stay updated with industry developments and new product releases to maintain competitive advantage. Regular testing and quality control will help you maintain high standards in your DTF printing projects.