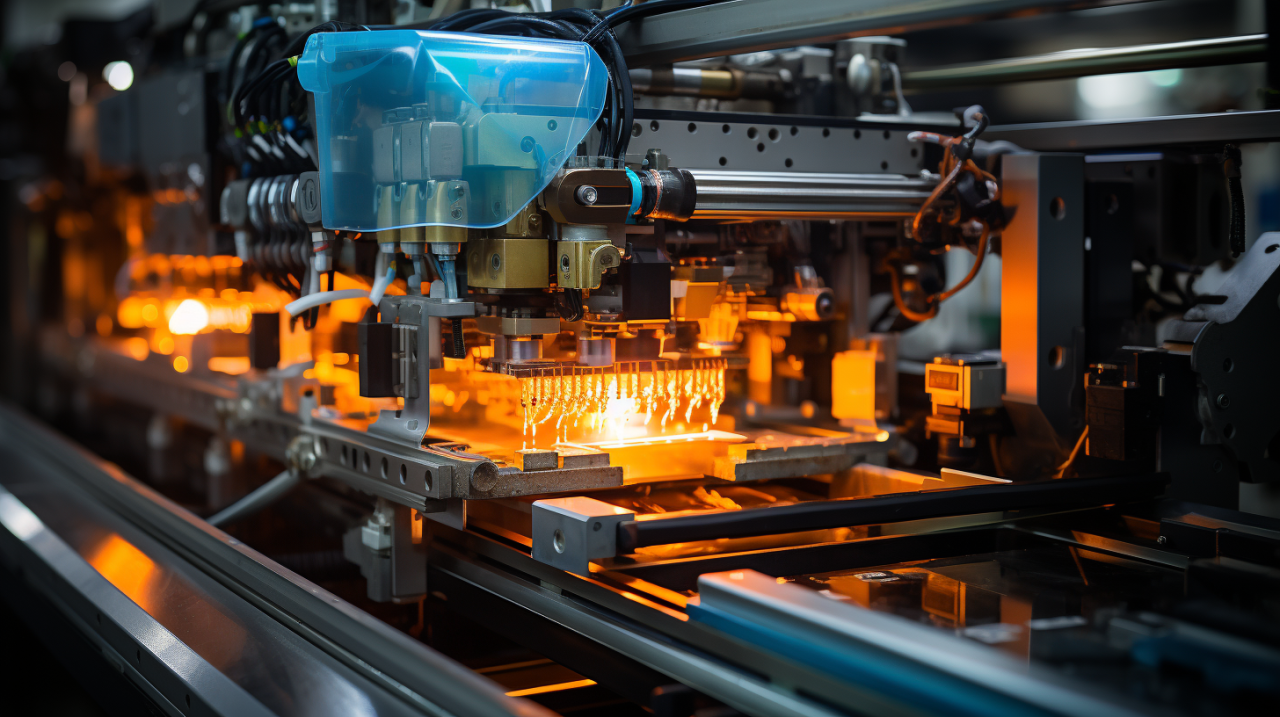

Injection molding has transformed manufacturing with its precision and efficiency, making it ideal for producing everything from medical devices to household items. This guide covers the basics and advanced techniques to help you improve your manufacturing processes and create high-quality products.

Introduction to Injection Molding

Injection molding is a manufacturing process used to produce parts by injecting molten material into a mold. It’s commonly utilized with materials like plastics, metals, and elastomers, offering consistent results, scalability, and cost-effectiveness for large production runs.

The technique is integral to industries ranging from automotive to consumer goods, making it a go-to solution for creating durable, high-precision components. However, success in injection molding goes beyond simply having the right equipment – it requires an understanding of precision, materials, and design.

What You’ll Learn

By exploring this guide, you will:

- Understand the critical role of precision in manufacturing.

- Learn the types of injection molding processes at your disposal.

- Discover how material selection impacts your results.

- Gain insights into design and quality assurance best practices.

- Uncover future trends shaping injection molding technologies.

Whether you’re an experienced engineer or new to manufacturing, this guide offers valuable insights to elevate your production capabilities.

The Importance of Precision in Manufacturing

Precision is the foundation of injection molding – even the slightest error can lead to defective parts, wasted materials, and increased costs. For industries like aerospace or healthcare, where tolerances are exceptionally tight, working with a reliable large-part injection molder ensures the highest level of accuracy and quality. Precision becomes even more crucial in these demanding sectors.

Benefits of Precision

- Reduced Waste: Precise molding lowers material waste, reducing costs and environmental impact.

- Consistency: High precision ensures that every part meets exact specifications, eliminating variability.

- Component Performance: Accurate molds produce parts that function optimally, improving product quality and durability.

Ultimately, investing in precision delivers long-term efficiencies and ensures that your products meet industry standards.

Understanding Injection Molding Machines

Injection molding machines are the lifeblood of this process. They consist of three main components:

- The Hopper (where raw material is loaded).

- The Barrel (where the material is heated and mixed into a molten state).

- The Mold (a cavity that shapes the molten material into the desired part).

Types of Machines

- Hydraulic Machines

- Traditional and cost-effective.

- Suitable for larger parts requiring high clamping force.

- Electric Machines

- Energy-efficient and precise. Ideal for processes requiring ultra-thin walls or complex geometries.

- Hybrid Machines

- Combines the strengths of hydraulic and electric systems, offering versatility and high output.

Choosing the right machine depends on your production volume, material, and tolerance requirements.

Types of Injection Molding Processes

Injection molding is a diverse field, offering several process options to address specific manufacturing needs. Here are the most common:

1. Thermoplastic Injection Molding

- Ideal for consumer products, automotive parts, and packaging.

- Materials include ABS, polypropylene, and nylon.

2. Overmolding

- Combines two or more materials to create a single part.

- Commonly used for ergonomic grips or seals.

3. Insert Molding

- Inserts pre-made components (like metal) into the mold for added functionality.

- Ideal for electronic housings and connectors.

4. Gas-Assisted Injection Molding

- Utilizes pressurized gas to form hollow sections within a part.

- Used in automotive and furniture manufacturing.

5. Micro Injection Molding

- Produces exceedingly small parts for medical devices or electronics.

- Requires precision beyond conventional methods.

Understanding the pros and cons of each process ensures you choose the right method for your application.

Material Selection for Optimal Results

The material you choose can significantly impact your product’s durability, appearance, and performance. Key considerations include:

- Strength and Flexibility: Materials like polycarbonate are ideal for impact resistance, while polyethylene offers pliability.

- Thermal Properties: High-heat environments may require materials like PEEK or nylon.

- Cost-Effectiveness: ABS is affordable for high-volume production, while specialty materials will increase costs.

Common Materials

- Plastics (polypropylene, ABS, polycarbonate)

- Elastomers (silicone, rubber for flexible parts)

- Metal Alloys (used in metal injection molding for advanced applications)

Select materials based on your product’s unique requirements, balancing cost, performance, and compatibility.

Design Guidelines for Injection Molding

The success of an injection-molded part often begins with its design. Following proven design guidelines ensures your mold functions efficiently, reducing defects and production issues.

Key Design Principles

- Uniform Wall Thickness

- Avoid warping by keeping walls consistent throughout your design.

- Draft Angles

- Include draft angles to allow parts to eject from the mold smoothly.

- Radii and Fillets

- Avoid sharp corners to reduce stress concentrations.

- Gate Placement

- Strategically position gates to prevent visible marks or weak points.

Collaborating closely with engineers and mold makers during the design stage can save time and resources down the line.

Best Practices for Quality Assurance

How do you ensure your parts meet rigorous standards? These quality assurance steps are critical in the injection molding process:

- Dimensional Inspection

- Regularly measure part dimensions to ensure they align with design specifications.

- Material Testing

- Test raw materials for consistency and quality before production.

- Process Monitoring

- Utilize real-time monitoring systems to track key parameters like temperature and pressure.

- Post-Production Testing

- Conduct functional tests to guarantee your product performs as intended.

Commit to these practices, and you’ll significantly reduce defects while maintaining customer satisfaction.

The Future of Injection Molding Technology

The injection molding industry is evolving rapidly, driven by digital innovation and sustainability. Major advancements to watch include:

Smart Factories

The integration of IoT and AI is creating “smart” manufacturing environments capable of optimizing processes and detecting issues in real-time.

Sustainable Practices

Recycled and bio-based materials are reducing the environmental footprint of injection molding.

Additive Manufacturing Integration

Combining 3D printing with injection molding allows for rapid prototyping and lower-cost molds, offering increased flexibility in product development.

Conclusion

Injection molding is an essential process used in various industries around the world. Understanding its key components, types of machines and processes, material selection, design principles, quality assurance practices, and upcoming technological advancements is crucial for successful product development. By continuously learning about new