AZP600X: Revolutionizing Technology with 3D Printing! The AZP600X represents a significant leap forward in 3D printing technology, offering unprecedented capabilities and versatility. This article explores how this innovative technology is shaping various industries and its potential impact on the future of manufacturing.

Introduction to the AZP600X

The AZP600X is a state-of-the-art 3D printer designed to meet the evolving needs of modern industries. It combines cutting-edge engineering with advanced materials to deliver superior performance and reliability. As businesses seek more efficient production methods, the AZP600X stands out for its ability to produce complex geometries with high precision and speed.

The Evolution of 3D Printing Technology

3D printing has evolved from a niche technology to a cornerstone of modern manufacturing. Initially used for rapid prototyping, it has expanded into production-grade applications across diverse sectors. The AZP600X exemplifies this evolution by integrating new materials and enhancing printing capabilities, driving innovation and efficiency in the industry.

Key Features of the AZP600X

Precision Printing Capabilities

The AZP600X is equipped with advanced technology that enables precise printing with exceptional accuracy. It achieves layer resolutions as fine as microns, allowing for the creation of intricate geometries and detailed structures. This level of precision is crucial for industries such as aerospace and healthcare, where component accuracy directly impacts performance and functionality.

Advanced Material Compatibility

Versatility is a hallmark of the AZP600X, which supports a wide range of materials including thermoplastics, metals, ceramics, and composites. This capability extends to both standard and advanced materials, such as carbon fiber-reinforced polymers and titanium alloys. The printer’s compatibility with diverse material properties enables manufacturers to meet specific application requirements without compromising on performance or durability.

User-Friendly Interface

Despite its sophisticated capabilities, the AZP600X features an intuitive user interface designed for ease of operation. The touchscreen control panel simplifies setup and monitoring, allowing users to manage printing parameters and workflows efficiently. Automated calibration and self-diagnostic tools further enhance usability, reducing downtime and optimizing productivity.

High-Speed Printing

With enhanced printing speeds, the AZP600X significantly reduces production cycles compared to traditional manufacturing methods. It utilizes advanced deposition techniques and optimized build processes to achieve rapid build rates without sacrificing print quality. This speed advantage is particularly beneficial for industries requiring quick turnaround times and agile production capabilities.

Scalability and Modular Design

The AZP600X is designed for scalability, accommodating varying production needs from prototyping to full-scale manufacturing. Its modular architecture allows for customization and upgrades, adapting to evolving industry demands and technological advancements. Manufacturers can expand their printing capabilities seamlessly, integrating multiple units for high-volume production or specialized applications.

Quality Assurance and Reliability

Built with robust components and precision-engineered mechanisms, the AZP600X ensures consistent print quality and reliability. Comprehensive quality assurance protocols, including real-time monitoring and error detection, minimize print failures and material wastage. This reliability is essential for industries where product integrity and performance are non-negotiable, providing confidence in every printed component.

Sustainability and Environmental Impact

As sustainability becomes a priority for industries worldwide, the AZP600X supports eco-friendly manufacturing practices. Additive manufacturing inherently produces less waste compared to subtractive methods, reducing material consumption and minimizing environmental footprint. The printer’s efficient energy usage and recyclable materials further contribute to sustainable production processes, aligning with global initiatives for greener manufacturing solutions.

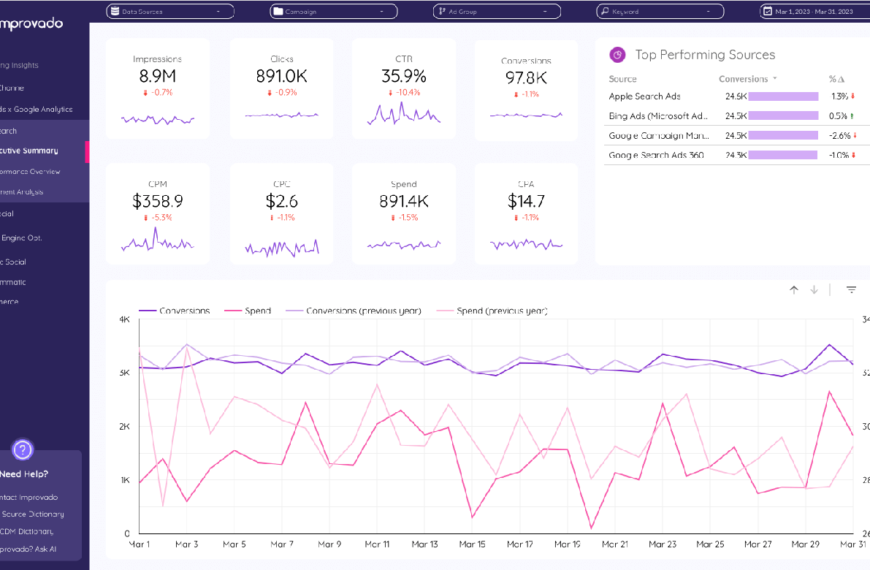

Integration with Digital Workflow

The AZP600X integrates seamlessly with digital design and workflow systems, enhancing collaboration and efficiency across the production chain. Compatibility with industry-standard CAD software and digital file formats facilitates seamless file transfer and version control. This digital integration streamlines design iterations, accelerates product development cycles, and supports agile manufacturing practices in today’s interconnected digital landscape.

These key features collectively position the AZP600X as a versatile and powerful tool for modern manufacturing, enabling businesses to innovate, optimize production processes, and meet evolving market demands with confidence.

Applications Across Industries

Healthcare Innovations

In the healthcare sector, the AZP600X facilitates the production of patient-specific medical devices and implants. Surgeons can now customize implants to match individual anatomies, improving patient outcomes and recovery times. This personalization is revolutionizing medical treatments, offering tailored solutions previously unattainable.

Automotive Sector Advancements

Automotive manufacturers leverage the AZP600X to prototype and manufacture complex parts with reduced lead times. From lightweight components to customized interior features, 3D printing enhances design flexibility and production efficiency in the competitive automotive industry.

Aerospace Industry Breakthroughs

In aerospace, the AZP600X supports the development of lightweight, high-performance components critical for aircraft and spacecraft. By printing intricate designs with advanced materials like titanium alloys, manufacturers achieve significant weight savings without compromising structural integrity, enhancing fuel efficiency and flight performance.

Benefits of Using the AZP600X

Cost Efficiency and Time Savings

- Reduced Material Waste: The AZP600X’s precise additive manufacturing process minimizes material waste compared to traditional manufacturing methods.

- Faster Prototyping: Rapid prototyping capabilities shorten product development cycles, reducing time-to-market for new innovations.

- Lower Production Costs: Streamlined workflows and on-demand printing capabilities help lower overall production costs by eliminating the need for costly tooling and inventory storage.

Customization and Prototyping Flexibility

- Design Freedom: Allows for complex geometries and customized designs that are difficult or impossible to achieve with conventional manufacturing techniques.

- Iterative Improvement: Enables quick iterations and modifications during the design phase, facilitating continuous improvement and innovation.

- Personalized Solutions: Tailors products to specific customer needs and requirements, enhancing customer satisfaction and market competitiveness.

Environmental Sustainability

- Reduced Carbon Footprint: Uses less energy and generates less waste compared to subtractive manufacturing processes, supporting sustainable production practices.

- Recyclable Materials: Supports the use of recyclable materials and biodegradable polymers, further reducing environmental impact.

- Localized Production: Reduces transportation-related emissions by enabling localized manufacturing, minimizing the environmental impact of global supply chains.

Enhanced Product Quality and Performance

- High Precision: Achieves tight tolerances and superior surface finishes, ensuring consistent quality across every print.

- Material Versatility: Compatible with a wide range of materials, including advanced composites and metals, to meet diverse application requirements.

- Durability and Reliability: Produces durable parts with excellent mechanical properties, suitable for demanding applications in aerospace, automotive, and healthcare industries.

Operational Efficiency and Scalability

- Improved Workflow: Simplifies production processes with automated features and intuitive user interfaces, enhancing operational efficiency.

- Scalable Solutions: Adapts to varying production volumes and requirements through modular design and scalable printing capabilities.

- Reduced Downtime: Minimizes downtime with automated maintenance routines and real-time monitoring, ensuring continuous operation and productivity.

Innovation and Competitive Advantage

- Technological Leadership: Stays ahead of competitors by leveraging cutting-edge additive manufacturing technologies and continuous innovation.

- Market Agility: Responds quickly to market trends and customer demands with agile manufacturing capabilities and rapid prototyping.

- Differentiation: Provides unique capabilities and solutions that differentiate products in competitive markets, fostering brand loyalty and market leadership.

These benefits underscore the AZP600X’s role as a transformative technology in modern manufacturing, offering tangible advantages across efficiency, sustainability, quality, and innovation.

You Also Like It:

Understanding the C0765 0x4750 and C0750 0x4765 Code

PUBG/BGMI 60fps (Smooth Extreme) Config – Minishortner

Challenges and Future Prospects

Overcoming Technological Limitations

Despite its advancements, the AZP600X faces challenges such as scalability for mass production and material limitations for specific applications. Addressing these challenges requires ongoing research and development to push the boundaries of what is achievable in additive manufacturing.

Future Trends in 3D Printing Technology

Looking ahead, the future of 3D printing with technologies like the AZP600X promises continued innovation. Trends such as bioprinting, multi-material printing, and on-demand manufacturing are expected to reshape industries further, driving new possibilities in customization, sustainability, and efficiency.

This structured approach provides a comprehensive overview of how the AZP600X is revolutionizing technology through 3D printing, highlighting its impact across various sectors and exploring both current benefits and future potentials.

FAQs about AZP600X: Revolutionizing Technology with 3D Printing

What is the AZP600X?

The AZP600X is an advanced 3D printer renowned for its precision, versatility, and capability to handle a wide range of materials. It is designed to revolutionize manufacturing processes by offering superior performance and efficiency.

How does the AZP600X contribute to innovation?

The AZP600X enables businesses to innovate by facilitating rapid prototyping, customization, and production of complex geometries that traditional manufacturing methods cannot achieve. Its advanced features and material compatibility support innovative product development across various industries.

What industries benefit from the AZP600X?

The AZP600X benefits industries such as healthcare, aerospace, automotive, and consumer goods. It is used for producing medical implants, aerospace components, automotive parts, and customized consumer products with enhanced efficiency and quality.

What are the advantages of using the AZP600X over traditional manufacturing?

The advantages include cost efficiency through reduced material waste, faster production cycles, and lower tooling costs. It also offers flexibility in design iterations, customization, and the ability to produce on demand, which traditional methods struggle to match.

How does the AZP600X support environmental sustainability?

The AZP600X promotes sustainability by minimizing material waste, using eco-friendly materials, and reducing energy consumption compared to conventional manufacturing processes. It enables localized production, reducing transportation-related emissions and supporting green manufacturing practices.

What are the key features that make the AZP600X stand out?

Key features include precision printing capabilities with high resolution, advanced material compatibility including metals and composites, a user-friendly interface for ease of operation, and scalability for varying production needs. These features collectively enhance productivity and product quality.

How does the AZP600X contribute to operational efficiency?

The AZP600X improves operational efficiency by streamlining workflows, reducing downtime with automated maintenance routines, and optimizing production processes. It integrates seamlessly with digital workflows, enhancing collaboration and accelerating time-to-market for new products.

What are the future prospects for the AZP600X technology?

Future prospects include advancements in multi-material printing, bioprinting applications, and further integration with Industry 4.0 technologies. These developments are expected to expand its capabilities and applications across industries, driving continued innovation in 3D printing technology.

How can businesses integrate the AZP600X into their manufacturing processes?

Businesses can integrate the AZP600X by leveraging its modular design and scalable printing capabilities. They can start with prototyping and gradually scale up production based on demand. Training employees on its user-friendly interface and optimizing workflows are key to maximizing its benefits.

Final Note About AZP600X: Revolutionizing Technology with 3D Printing

In conclusion, the AZP600X represents a significant advancement in 3D printing technology, poised to revolutionize various industries with its precision, versatility, and efficiency. From enhancing product quality and customization to promoting sustainability and operational efficiency, the AZP600X offers tangible benefits that propel innovation and competitiveness in today’s dynamic market landscape.

As businesses continue to explore new possibilities in manufacturing, the AZP600X stands as a testament to the transformative power of additive manufacturing. Its ability to streamline production processes, reduce costs, and accelerate time-to-market underscores its importance as a strategic investment for future-forward enterprises.

Looking ahead, the AZP600X’s role in shaping the future of manufacturing is promising, with ongoing advancements and applications across diverse sectors. Whether in healthcare, aerospace, automotive, or consumer goods, its impact extends far beyond traditional production methods, paving the way for sustainable growth, technological leadership, and unparalleled innovation.

For businesses seeking to stay ahead in a rapidly evolving industry landscape, integrating the AZP600X into their operations represents not just an opportunity but a strategic imperative to thrive in the era of advanced manufacturing.

You Also Like It:

willian da silva cavalcante willian da silva cavalcante 391.200.268/11

Where Are Amber Reflective Studs Found on a Motorway